AGITATED NUTSCHE FILTER/DRYER Manufacturers in India

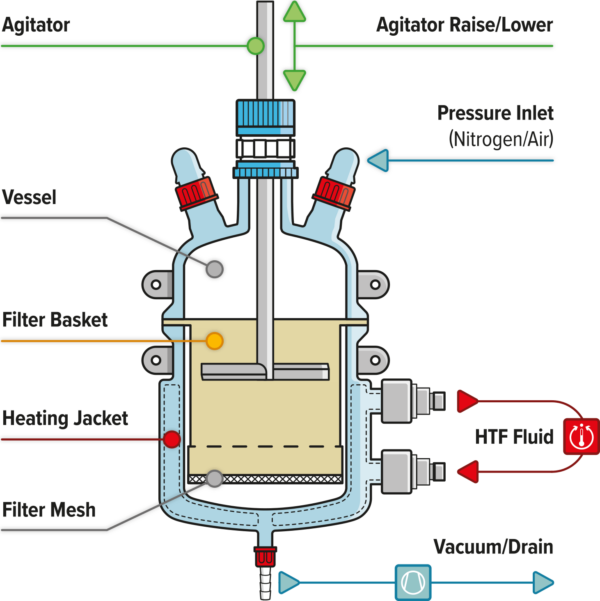

Our state-of-the-art Agitated Nutsche Filter/Dryer works as a closed system, eliminating any possibilities of atmospheric pollution from toxic fumes generated from the slurry. It is specifically designed to separate solids from liquids under controlled conditions. The rest of the drying process is removed by the process of evaporation to obtain ultimate dry products.

Our products provide a diverse services and activities by maneuvering its movement of vertical and rotational directions simultaneously by push buttons switches/PLC.

TECHNICAL DATA SHEET

| MODEL NO. | IDT ANF-0.5 | IDT ANF-1 | IDT ANF-2 | IDT ANF-3 | IDT ANF-4 | IDT ANF-5 | IDT ANF-8 | IDT ANF-7 |

|---|---|---|---|---|---|---|---|---|

| Working | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 |

| Filtering | 0.68 | 1.02 | 1.82 | 2.7 | 3.2 | 4.7 | 5.7 | 6.5 |

| RPM | 20 | 20 | 20 | 15 | 12 | 12 | 12 | 10 |

| Motor | 5 | 5 | 7.5 | 7.5 | 10 | 12.5 | 15 | 15 |

| H.P. | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Internal dia. | 1000 | 1200 | 1600 | 2000 | 2200 | 2600 | 2800 | 3000 |

| Over height | 3300 | 3700 | 3800 | 4200 | 4400 | 4500 | 4900 | 5100 |

Material Used for AGITATED NUTSCHE FILTER/DRYER

Carbon Steel

Stainless Steel

Super Stainless Steels

Hastelloy

BENEFITS AND FEATURES:

- Maximum solvent recovery is possible

- Explosion or fire hazard on account of spillage is eliminated

- Negligible Man Power required

- Possibility of doing reaction filtration, washing and distillation in the same equipment

- Very effective washing of cake due to re-slurring resulting in thorough particulate washing and reduces number of washes, and volume of wash liquor

- Drying process is also available